Quieter. Tight. Durable.

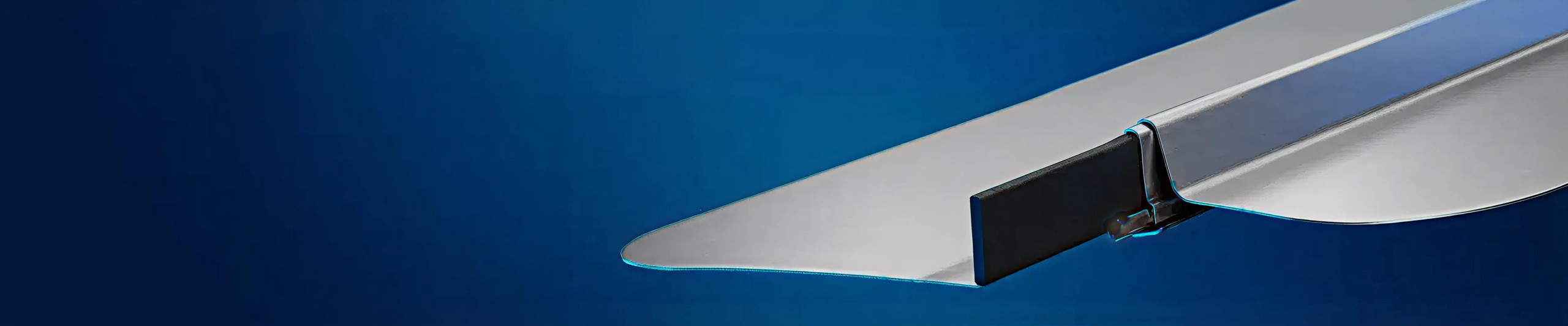

When metal roofs become a challenge due to rain noise, condensation, corrosion or complicated sealing details, it takes more than standard solutions. The QCC (Quiet Closed Coating) roof system is a patented system innovation that rethinks metal roofs: faster installation, less material used. QCC also combines several functions in a single factory coating.

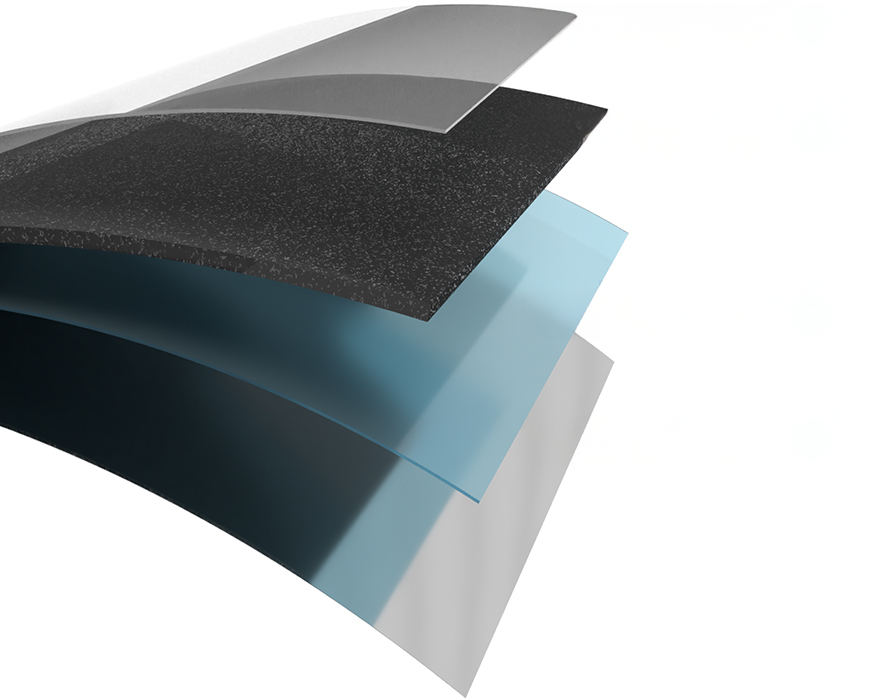

This is made possible by the innovative and versatile technology basis: MEFOFLEX® from HUEHOCO. Mefoflex is an extruded, foamed EPDM elastomer coating that is firmly bonded to the metal in the factory.

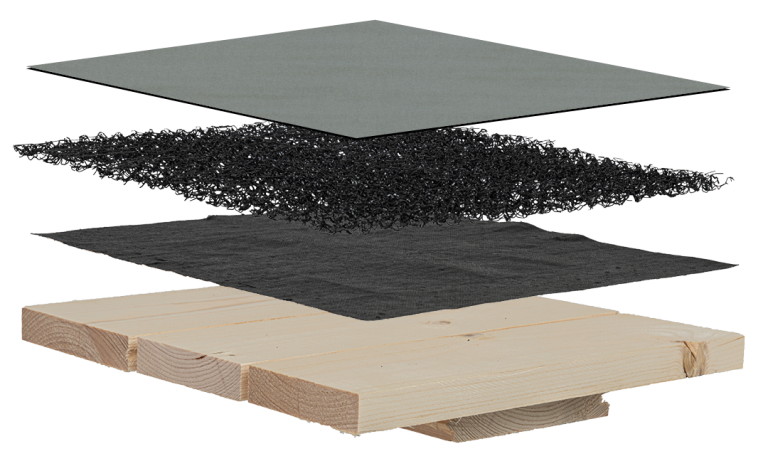

The result is a modern metal roof coating that not only protects, but also insulates, seals and prevents condensation. It therefore replaces the various layers of conventional systems.

MEFOFLEX® –

the technology behind QCC

MEFOFLEX® is a foamed EPDM elastomer coating that is applied directly to metal strips using an extrusion process. The coating is firmly bonded to the metal and remains permanently elastic even at extreme temperatures.

- Layer thickness: approx. 0.35 mm

- Temperature range: -40 °C to +130 °C permanently elastic

- Suitable metals: e.g. steel, stainless steel, aluminum alloys, zinc, copper, non-ferrous metals

- Belt widths: 400-800 mm, individual end widths possible

- Functional principle: 3 effects in one layer

MEFOFLEX® – simultaneously provides for:

- Sound attenuation

- Sealing

- Corrosion & condensate protection

It is precisely this multiple effect that makes MEFOFLEX® the ideal basis for system solutions such as the QCC roof system – and for many other applications.

For quality that does not depend on the weather and building site. A decisive difference to many classic roof coatings: MEFOFLEX® is not applied on site, but is continuously extruded at the factory. This means

- Controlled process instead of construction site risk

- Reproducible layer thickness

- Consistent adhesion

- High process reliability

MEFOFLEX® – for roofs and many other areas

The QCC roof system is a tangible example of how MEFOFLEX® works. The technology is also suitable for:

- Facades

- Window sills

- Ventilation / building technology

- Machine and vehicle construction

and other applications where sealing, insulation, damping and protection are required.

Find out more now

Any questions?Are you planning a metal roof and want to avoid noise, condensation and leaks right from the start?

Request technical documentation on the QCC roof system powered by MEFOFLEX® now – including system structure, data sheet and application recommendations.

FAQs on the QCC metal roof coating

In short: MEFOFLEX® is more than a simple EPDM coating. It is a factory-extruded elastomer or EPDM foam coating that is firmly bonded to metal. It therefore fulfills exactly what many people are looking for in a modern metal roof coating: permanently elastic protection, damping and an additional functional layer.

MEFOFLEX® is applied to metal strips using an extrusion process and forms a foamed, elastic rubber layer. The coating remains permanently elastic over a wide temperature range (from -40 °C to +130 °C). It is also designed to be suitable for various metals (e.g. steel, stainless steel, aluminum alloys as well as zinc, copper and other non-ferrous metals).

This means that MEFOFLEX® is not “just” a metal roof coating, but a technological basis that performs several functions in system solutions such as the QCC roof system: sound insulation, waterproofing, corrosion and condensation protection.

The QCC roof system is not a classic EPDM membrane system, because with EPDM roof membranes, a waterproofing membrane is laid and mechanically fastened or bonded. With the QCC system, the “rubber coating” is already applied to the metal underside at the factory and is used systemically during installation.

This results in various advantages. The QCC roof system reduces the typical weak points of classic metal roof systems: The waterproofing is not just “on top”, but an integral part of the roof system. Even in demanding projects, this means: less material, fewer layers, fewer sources of error – and still a high sealing and protective effect.

The QCC roof system is suitable for many common metal roof materials and constructions where waterproofing, sound insulation and condensation protection are required at the same time:

- Zinc

- Aluminum

- Copper

- Stainless steel

- Steel

- Aluminum alloys and

- Non-ferrous metals

As an elastic metal roof coating, the QCC roof system powered by MEFLOELFEX can do more than just “protect”: it can dampen, seal and significantly increase the service life of a metal roof.

Elasticity is particularly important with metal, because metals work – due to temperature changes, wind loads and mechanical vibrations. This results in important advantages of an elastic roof coating:

- Vibration damping: reduces noise from rain/hail

- Sealing effect: protects critical areas from water ingress

- Corrosion protection: Barrier against moisture and contact corrosion

- Condensation protection: reduces or prevents condensation

- Durability: resistant to ageing, water, temperature and other stresses

- System simplification: fewer additional layers such as separating layers/nonwovens required

When rain or hail hits metal, the energy is transmitted as structure-borne sound via the sheet metal. Conventional systems often try to mitigate this by using separating layers, fleece or additional insulating layers.

In the QCC system, sound insulation works directly via the elastic coating: the EPDM rubber layer contains enclosed air cells that act like a damping buffer: they reduce the transmission of vibrations and thus significantly reduce rain and hail noise.

It significantly reduces condensation and prevents condensation on the underside of the sheet. The coating acts as an anti-condensation coating and forms a barrier against moisture. At the same time, contact corrosion is reduced because the metal underside is not “naked” but permanently protected.

Condensation occurs when warm air meets cold metal surfaces. This is a common problem, especially on industrial and warehouse roofs, and usually manifests itself as dripping water, increased risk of corrosion and actual moisture damage. This is where the QCC system powered by MEFOFLEX can be a real game changer.

The QCC roof system can be used from a roof pitch of just 1.5° – and is therefore also suitable for very flat roof shapes. This is a clear advantage over many classic metal roof constructions, where flat pitches require additional measures.

In most cases, a structured separation layer can be dispensed with, even on flat pitched roofs, because the rubber underlayer does not allow moisture to pass through and adheres directly to the metal. This is a significant cost advantage, as separating layers mean material, time and potential for errors.

Would you like to know exactly whether MEFOFLEX® or the QCC system is suitable for your project?

Request technical information – including system design, specifications and application notes.