When it gets hot

htze – High-Temperature Zero Emission CoatingFor over 10 years, HUEHOCO has been the market leader for coated, hot-dip coated material with HTZE (High-Temperature-Zero Emission) lacquers for beam shields in headlights, or heat conducting plates. At moderate temperatures, the HTZE coating material does not emit any substances that could be permanently deposited on the headlamp glazing. Therefore, annealing at high temperatures and the associated costs to eliminate such substances is basically not necessary. Excluded from this are process steps during further processing that leave residues on the surface, for example.

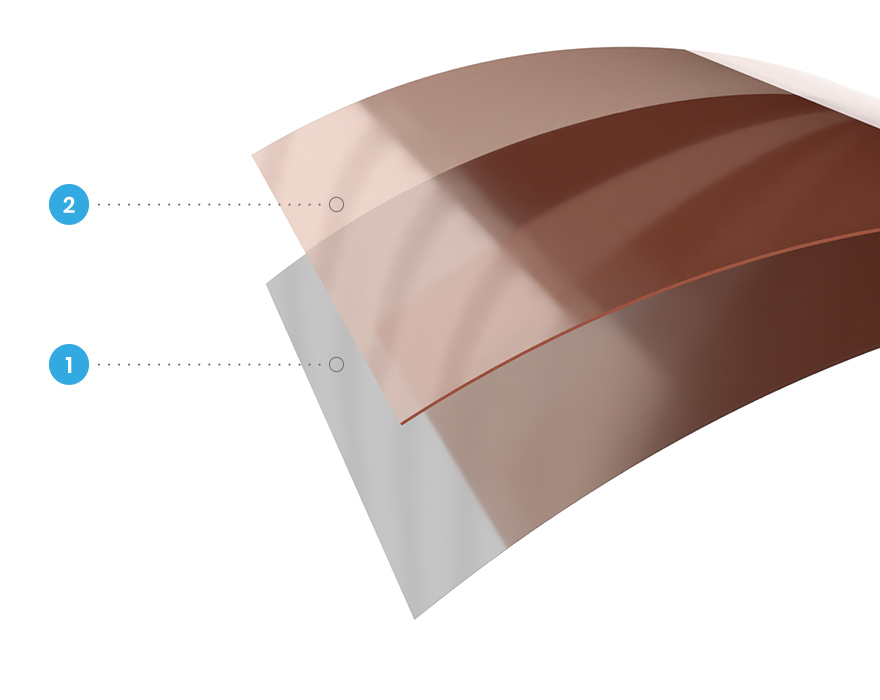

Carrier material

- Metal types: mainly steel, hot-dip galvanized steel, stainless steel

- Belt widths of 400-800 mm possible (different for beam diaphragms); can be cut to individual end widths

- Tape thicknesses of the carrier material from 0.20-1.00 mm possible

- Max. Coil weight of 5000 kg

HTZE coating

- We offer various HTZE coatings with different gloss levels (from 0 to 30 GU at 60°C). On request, we can also develop new coatings specifically for your application in our development laboratory.

Industry References

Below you will find some examples from our industry solutions with HTZE coatings, such as heat deflector plates painted on one side and beam shields in headlights. We are sure to find a suitable solution for you as well.

Request nowINdIVIDUAL MAnAGEMEnT

More economy

Of course, we will deliver the coated coils in the presentation of your choice. Whether individual single ring packaging with and without cardboard core or wound goods on cardboard core, plastic spools or metal winding racks.

Coiled metal strips

More running lengthIn order to increase the running lengths, we join the metal strips using the latest welding technology and oscillatingly wind them onto new spools. In this way, we reduce set-up and downtimes in your production.

- Strip widths from 1.5 mm up to 60 mm

- Extension of the running length to over 200,000 meters in one core depending on the material

- Individual installation widths from 100 to 400 mm

- Special decoiling racks with winding widths of 800 mm and maximum winding weights of 2,500 kg