A NEW DIMENSION

THE RUBBER COATING

OF METALS

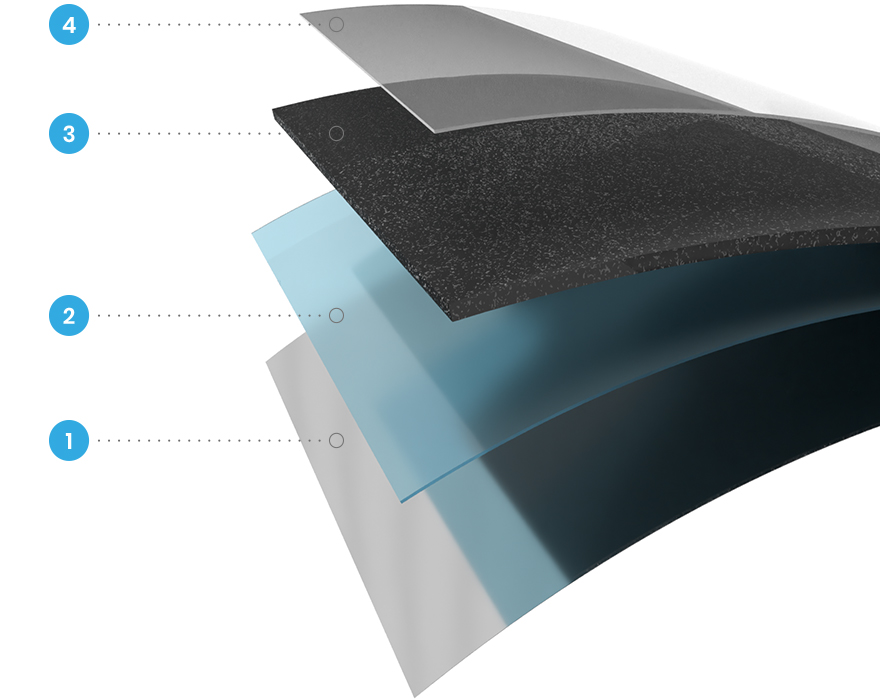

Foamed rubber MefoFlexWith our new HUEHOCO rubber extrusion line, we are able to apply foamed elastomer layers in layer thicknesses from 200 up to 2,000 μm in a single pass – on one or both sides. This not only enables us to achieve enormous energy savings, but also to massively reduceCO2 emissions at high rubber layer thicknesses compared with the liquid coating previously used. The positive impact on the environment is so great that the German Ministry of the Environment has found the investment worthy of support.

Carrier material

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths of 400-800 mm possible; can be cut to individual end widths

- Tape thicknesses of the carrier material from 0.20-1.00 mm possible

- Max. Coil weight of 8000 kg

Bonding agent

- Adhesion promoter systems as 1-layer or 2-layer application (primer/topcoat)

MefoFlex FoamRubber Coating

Foamed elastomer layers (200 to 2000 μm), both single-sided and

can be coated on both sides.

- Natural rubber (NR)

- Polyisoprene (IR)

- Butadiene styrene (SBR)

- Polybutadiene (BR)

- Polychloroprene (CR)

- Butyl (IIR)

- Chlorosulfonated polyethylene (CSM)

InLine top coatings

- Color adjustment of the top coating possible

- Additional antiblock or bonded coating possible

- Plastic film / paper as intermediate layer optionally possible

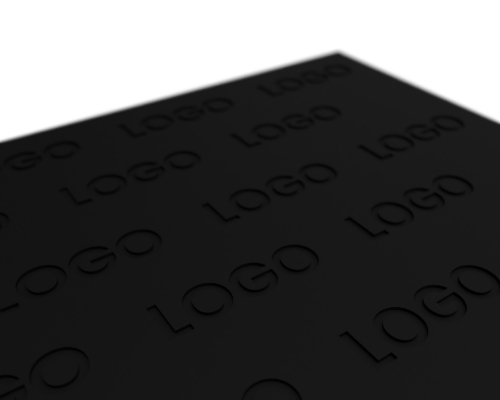

- Optional surface texturing (structures, logos, motifs)

Design options

Individualize your productWe also offer various visual or functional finishes for MEFOFLEX foam rubber coatings. This allows us to imprint structures or motifs and apply additional decorative or functional coatings.

Request now

Industry References

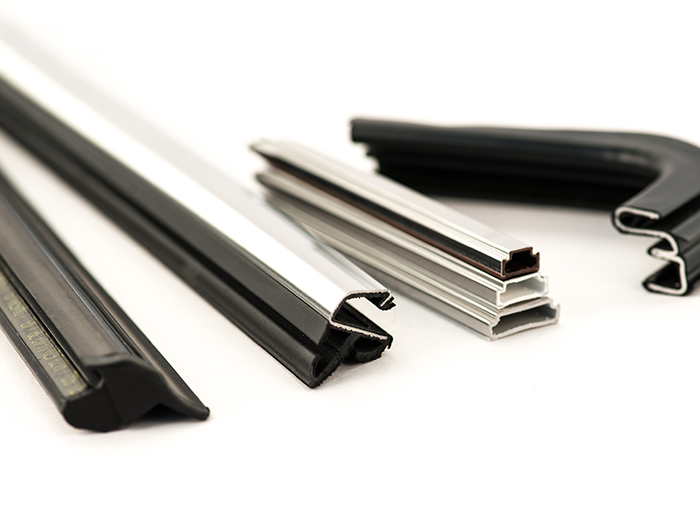

Below you will find some examples from our industry solutions. There are a wide range of applications for rubber-to-metal bonding. We are sure to find a suitable solution for you as well.

Request nowINdIVIDUAL MAnAGEMEnT

More economy

Of course, we will deliver the coated coils in the presentation of your choice. Whether individual single ring packaging with and without cardboard core or wound goods on cardboard core, plastic spools or metal winding racks.

Coiled metal strips

More running lengthIn order to increase the running lengths, we join the metal strips using the latest welding technology and oscillatingly wind them onto new spools. In this way, we reduce set-up and downtimes in your production.

- Strip widths from 1.5 mm up to 60 mm

- Extension of the running length to over 200,000 meters in one core depending on the material

- Individual installation widths from 100 to 400 mm

- Special decoiling racks with winding widths of 800 mm and maximum winding weights of 2,500 kg